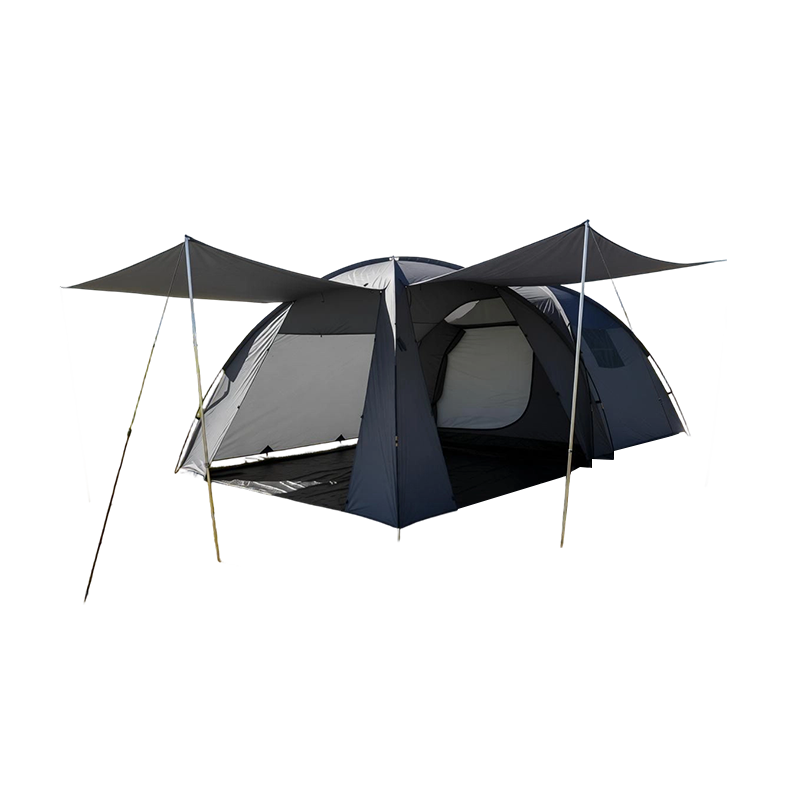

Tightening Environmental Regulations Press Outdoor Industry to Transition to Green Supply Chains

With the advancement of the EU's proposed Ecodesign for Sustainable Products Regulation and major global brands committing to "net-zero carbon" pledges, the green revolution in the outdoor industry has evolved from a marketing concept to the core of the supply chain. In the future, a product's environmental footprint will become a critical threshold for entering international markets.

The new regulations focus not only on the recycled material content and recyclability of the product itself but also assess its entire lifecycle carbon footprint, covering raw material sourcing, production energy consumption, transportation logistics, and end-of-life disposal. This poses a significant challenge to the traditional tent manufacturing industry, which heavily relies on petrochemical-derived materials like nylon and polyester.

Leading companies are taking active steps. It is reported that some Chinese manufacturers have begun collaborating with material technology firms to develop bio-based fabrics, fluorine-free eco-friendly waterproof coatings, and to optimize production processes to reduce energy consumption and wastewater. Companies like Kaima Outdoor have also stated that they have established task forces to evaluate and integrate renewable materials, aiming to provide customers with "green product" solutions that comply with future regulations. This transition is not only a challenge but also a key opportunity for the industry to reshuffle and build long-term competitiveness.

-

Sep 25, 2025-BY ADMIN

With the advancement of the EU's proposed Ecodesign for Sustainable Products Regulation and major global brands committing to "net-zero carbon" pledges, the gre...READ MORE

-

Sep 25, 2025-BY ADMIN

According to the newly released Global Outdoor Equipment Market Report, driven by new trends like "micro-cations" and "solo camping," the global demand for ligh...READ MORE

-

Sep 25, 2025-BY ADMIN

The Zhejiang Provincial Department of Commerce recently announced the annual list of "Zhejiang Export Famous Brand" enterprises. Ningbo Kaima Outdoor Products C...READ MORE

-

Sep 25, 2025-BY ADMIN

Ningbo Kaima Outdoor Products Co., Ltd. announced today that it has entered into a three-year strategic cooperation agreement with "Alpine Summit Gear," a leadi...READ MORE

English

English